INTRODUCTION

In interior decoration, Hat Furring Channel can be used as the framework for walls and ceilings. For instance, when carrying out the construction of hat furring channel gypsum board partition walls, small hat furring channel can serve as the main load-bearing framework, fixed to the ground, ceiling and side walls, and then the gypsum boards are installed on the steel frame to form a smooth and solid partition wall. In ceiling projects, small channel steel frame can form the steel system of the ceiling, bearing the weight of the ceiling materials and making the ceiling more solid and flat.

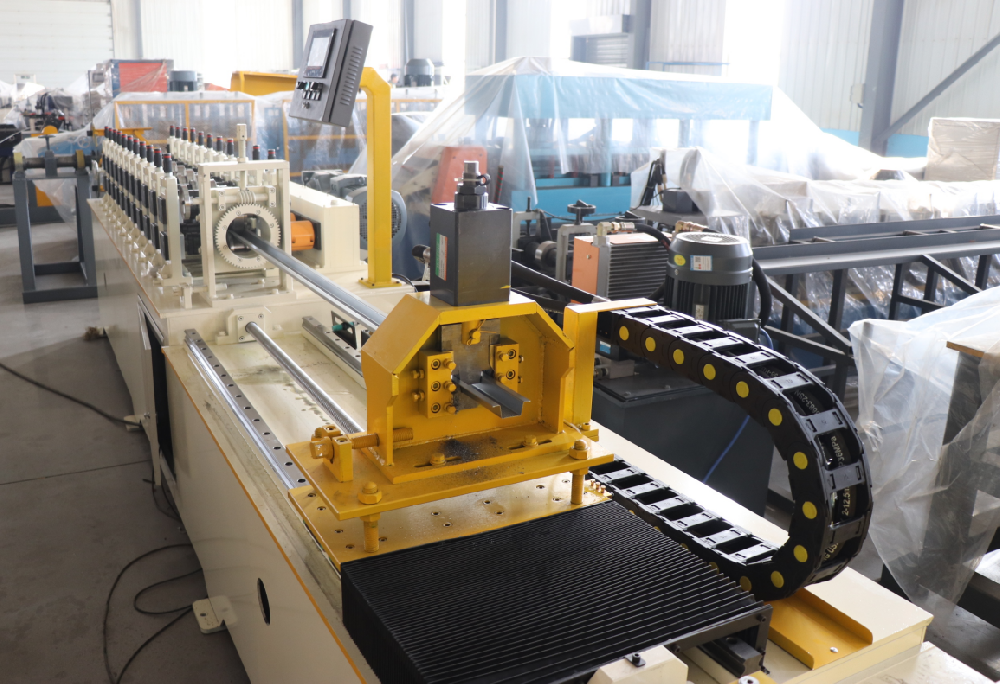

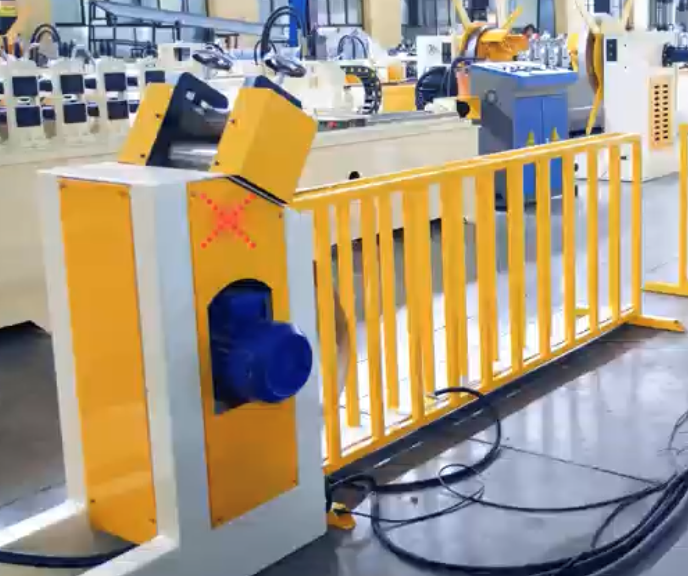

ZTRFM High Speed Hat Furring Channel Roll Forming Machine is one high-speed, energy-efficient and intelligent production line to produce the hat furring channels for builidings.

The features of this Hat Furring Channel Roll Forming Machine:

https://youtu.be/Daezes8SXQI?si=yxlsWpi3ceYwmlvI

1. high speed: 50 m per minutes with punching

2. Transmission: by gearbox

3. Material storage cages: with our technology patent

4. Automatic sizes adjustment: width range from 80mm -200mm

5. Semi-package system:save space and money for factory

The technical specifications of a high speed Hat furring channel roll forming machine:

1、 Uncoiler & Feeder Device:

l Capacity:3 tons

l Coil width: max 800mm, as customer’s request

l Working type:passive type with brake to stop the uncoiler; hydraulic coil core expansion

l 4 support arms design: support the coil and prevent crease when uncoiling

l Make sure a high-speed feeding of the material

l Hand wheel of the feeder:adjust the gap of the roller according to the thickness of the material

2、Material Storage Cage:

l Structure:pipe welded cage with our patents

l Prevent material crease and run away

l Storage material to meet the high-speed production

l Patented technology design

3、High-speed Punching Machine:

l Make sure the high punching speed to 120-200 times/min;

l Motor: 7.5 kw servo motor

l Small size saves space and small noise

l Easy to change molds

l Capacity:25 tons

4、Roll Forming Machine:

l Frame structure: arch frame is connected with the body by bolts and nuts

l Roller Station: 11 stations

l Roller material: Cr12mov,finishing after quenching heat treatment, to ensure that high rotation does not produce heat, to ensure hardness and urgent service life

l Turkey head: 5 rollers have rotation and straightening action

l Transmission type:by gearbox

l Speed:0-50m/min

l The operation touch screen mounted on the forming machine can save space

5. Cutting System

l Automatic hydraulic driven method

l no-stop cutting design: moving by the servo motor

l Material of cutting blade:GCr12Mov

l Dust cover design

6.Oil Station

● Work type:Hydraulic driven

● Hydraulic power:machine 7.5 kw

● With cooling fan device

7. Receiving system

You also can choice the full automatic stacker and package system, the prictures for your reference.

If you have any questions or need help: feel free to contact with our team.

+86 15227520688

Add.:N0.4 ROAD, ECONOMIC DEVELOP ZONE, BOTOU COUNTY, CANGZHOU CITY, HEBEI PROVINCE, CHINA

NAVIGATION

RECRUIT DEALERS